Coolant System

Coolant System

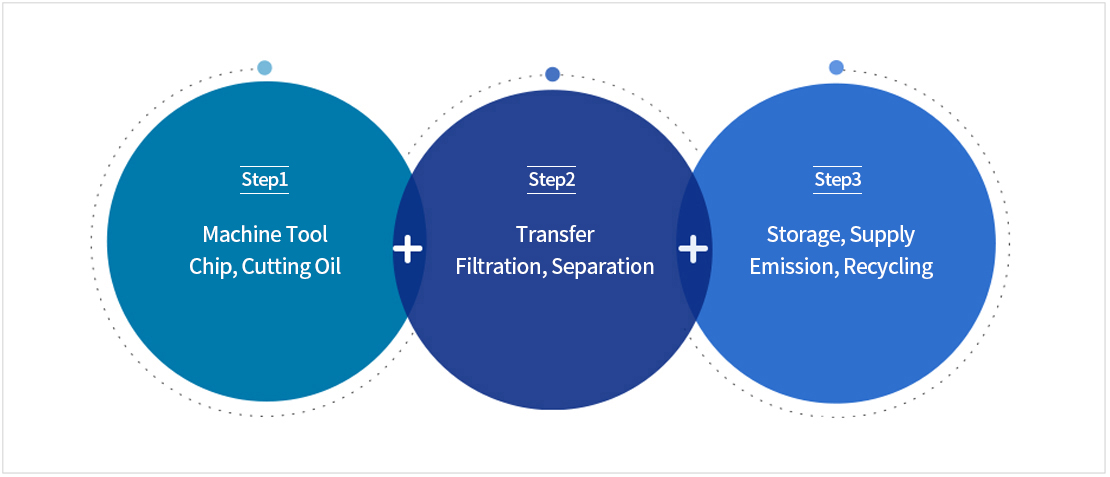

* Please refer to the picture below to select the equipment and if you have any difficulties, please contact Online Counseling or telephone on the website and we will kindly inform you.

Principle Of Basic Technology

Main Production Distribution

- General purpose equipment design and production of Conveyor & Coolant System

- Design and production of dedicated equipment cost Conveyor & Coolant System

- Centralized Chip and Coolant Handling Unit Design.Production

Review items when selecting filtering system

1. The object of a device

Is it to increase the processing precision?

Is it for the protection of the tip?

Is it for the protection of the Pump?

Is it for Nozzle's blindness?

Is it for removing the heat from the process?

Is it for cleaning work?

Is it for the removal of the chip?

Is it for the separation of oil?

2. Type of cutting oil

water-soluble: determination of the properties of a fluid; foaming; corrosion-resistant; admixture of oil

Planetary: viscosity, effect on temperature, corrosivity

3. Processing condition

Processing speed, special water processing status

Planetary: viscosity, effect on temperature, corrosivity

4. Shape and incidence of chips

What is the powder or curl condition, floatation condition, and amount of occurrence?

5. Material of work

Is it magnetic, involuntary, homogenous? Is it a mixture of different materials?

Selection of Coolant System

- X Bad(nonconformity)

- △ Normal

- O Good (fit)

| Chip | Filtration Degree | Conveyor |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Quality Of The Material | Geometry / Length | Hinge | Scraper | Screw | M/G | Hinge | Scraper | Hinge Scraper Drum with 2 Steps |

||

| Scraper | Drum | Drum | ||||||||

| FC FCD |

Powder 90% ↑ / Sand ↓ |

General | 300μ ↑ | X | O | X | O | X | X | X |

| Low | 200μ ↑ | X | O | X | O | X | X | X | ||

| Middle | 100μ ↑ | X | △ | X | O | X | △ | X | ||

| High | 50μ ↑ | Add Add Addition Option | ||||||||

| Maximum | 30μ ↓ | |||||||||

Short Curl 10% ↓ / 50mm ↓ |

General | 300μ ↑ | X | O | △ | O | X | O | X | |

| Low | 200μ ↑ | X | O | X | O | X | O | X | ||

| Middle | 100μ ↑ | X | O | X | O | X | △ | X | ||

| High | 50μ ↑ | Add Add Addition Option | ||||||||

| Maximum | 30μ ↓ | |||||||||

| Steel |  Short Curl90% ↑ / 50mm ↓ |

General | 300μ ↑ | O | △ | O | △ | △ | △ | O |

| Low | 200μ ↑ | O | O | △ | △ | △ | X | O | ||

Long Curl 90% ↑ / 150mm ↓ |

Middle | 100μ ↑ | O | O | △ | △ | △ | X | O | |

| High | 50μ ↑ | Add Add Addition Option | ||||||||

| Maximum | 30μ ↓ | |||||||||

| AL |  Short Curl 10% ↓ / 50mm ↓ |

General | 300μ ↑ | X | X | O | X | △ | O | △ |

| Low | 200μ ↑ | X | X | O | X | △ | O | △ | ||

| Middle | 100μ ↑ | X | X | △ | X | △ | O | △ | ||

| High | 50μ ↑ | Add Add Addition Option | ||||||||

| Maximum | 30μ ↓ | |||||||||

Long Curl 90% ↑ / 150mm ↓ |

General | 300μ ↑ | △ | X | O | X | O | X | O | |

| Low | 200μ ↑ | △ | X | △ | X | O | X | O | ||

| Middle | 100μ ↑ | X | X | △ | X | O | X | O | ||

| High | 50μ ↑ | Add Add Addition Option | ||||||||

| Maximum | 30μ ↓ | |||||||||

| ※ Changes can be made depending on equipment characteristics, type of workpiece, etc. | ||||||||||